A Baffle-ing problem

The soffit is any finishing material installed to cover the underside of a roof overhang. The soffit area usually runs most of the perimeter of the building but not always. Apart from aesthetic purposes like covering the exposed rafters making up the underside of your roof’s overhang, soffits provide attic ventilation through perforations or vents in the material.

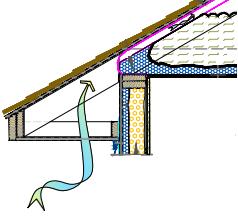

Spray foam applicators need to completely seal this area with spray foam insulation when creating an unvented attic. But as you can see in the picture, this area is typically exposed to the outside with no backing material or substrate to spray to. Depending on how the roof line height corresponds to the height of the exterior wall, this opening can vary from 3.5” up to a couple of feet in some cases. Building up enough spray foam to bridge these gaps is not practical or recommended.

Spray foam applicators turned toward cardboard baffle vents to overcome this installation challenge. Baffle vents primarily channel airflow from the exterior soffit vents up into the attic space, but they also prevent loose-fill insulation, like blown-in cellulose or fiberglass, from clogging up the soffit vent. For spray foam applicators, pre-cut cardboard baffles that are installed and stapled in place provide a cost-effective substrate for spray foam insulation. In this installation method, spray foam covers the baffle’s air discharge area, which leaves an air gap of approximately 1.5” between the backing of the cardboard baffle and the roofline. This is our recommended installation method. However, it’s the lower flap of the baffle that often creates installation problems.

Spray foam applicators turned toward cardboard baffle vents to overcome this installation challenge. Baffle vents primarily channel airflow from the exterior soffit vents up into the attic space, but they also prevent loose-fill insulation, like blown-in cellulose or fiberglass, from clogging up the soffit vent. For spray foam applicators, pre-cut cardboard baffles that are installed and stapled in place provide a cost-effective substrate for spray foam insulation. In this installation method, spray foam covers the baffle’s air discharge area, which leaves an air gap of approximately 1.5” between the backing of the cardboard baffle and the roofline. This is our recommended installation method. However, it’s the lower flap of the baffle that often creates installation problems.

In a typical cardboard baffle installation, the installer often staples the lower baffle flap to the interior edge of the top plate. What may seem like a good practice incidentally causes a break in a sealed attic. The gap between the lower flange and the baffle can be 1/8-1/4”, which is enough to allow air into the conditioned space as shown here.

Fortunately, this is an easy problem to solve. Simply make sure that lower flange of the cardboard is installed as far back as possible, or our preferred approach, just attach the baffle to the outside of the wall.